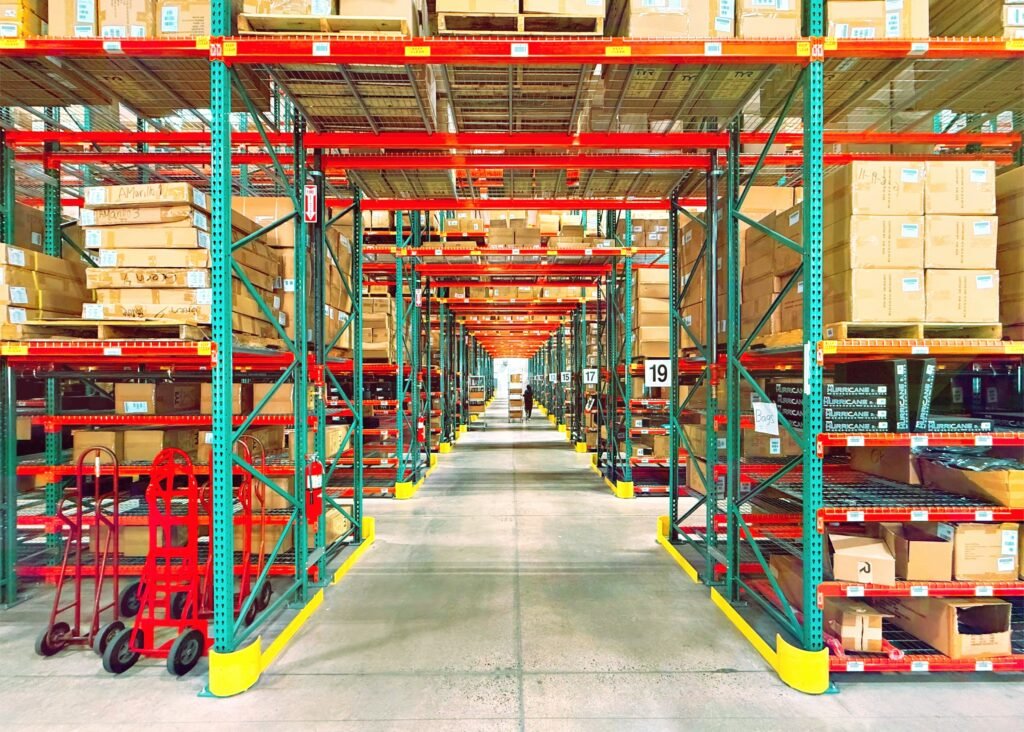

As Texas warehouses expand, racking permit compliance becomes critical for safe, efficient growth. Learn how to stay ahead while scaling smart.

If you’re running a warehouse in Texas, you’re probably used to fast-moving operations, shifting inventory needs, and constant layout changes. But one thing that often gets overlooked during growth phases? Racking permit compliance.

Most facilities treat it like a one-time hurdle during construction but the truth is, as your warehouse evolves, so do your permitting obligations. Ensuring compliance with racking permitsis about building the kind of infrastructure that can safely and legally support your growth.

Table of Contents

ToggleWhy Growth Often Triggers a Permit Review

Let’s say you’re adding a new product line and need more racking to store it or maybe you’re installing new automation or converting standard racks into narrow-aisle systems. These changes might seem minor operationally, but they can impact your code compliance in major ways.

Common triggers that require a permit reassessment include:

- Installing taller or denser racking systems

- Changing from static to dynamic storage such as pushback or pallet flow

- Adding mezzanines or modifying egress routes

- Increasing daily throughput with additional shifts

- Reconfiguring rack orientation or aisle spacing

If your layout or load changes, so does your permit requirement and in Texas, inspectors take notice.

What “Compliance” Really Means During Expansion

Getting a racking permitis proof that your layout is structurally sound and fire-code compliant. Here’s what ongoing racking compliance actually requires.

- Current engineered drawings that reflect your real-world setup

- Accurate load calculationsthat align with your actual inventory

- Verified sprinkler coverage and clearance based on new rack heights

- Safe egress spacing for forklifts and personnel

- Confirmation that any changes to the structure or use haven’t invalidated prior approvals

Many warehouse operators don’t realize their permit may no longer be valid once they change equipment or reconfigure the layout. That’s a risk not worth taking, especially when compliance violations can lead to revoked occupancy certificates or shutdowns.

How Texas Codes Differ from Other States

Each municipality in Texas enforces local permitting codes, but some consistent requirements stand out across the state. Here are a few that make Texas-specific compliance a unique challenge.

- Sprinkler tie-ins and clearance:Most cities require that your racking system not interfere with fire suppression equipment, and that you meet vertical clearance rules based on your commodity class.

- Egress compliance:Emergency access pathways must meet width and travel distance requirements.

- Seismic and structural requirements:While not as intense as in California, Texas still requires certain racking systems to be PE-stampedbased on load and soil conditions.

- Permitting inspections:Permits often include pre-installation and post-installation inspections by local fire marshals or building departments.

Whether you’re in Waco, Dallas, or San Antonio, your racking system needs to match what’s on file with your local authority. Otherwise, you’re out of compliance.

Streamlining Permits for Fast-Paced Operations

If you’re expanding or modernizing your warehouse, racking permits can feel like a bottleneck. When built into your planning process, they can actually support smoother, faster growth. Here’s how to make compliance a strength instead of a slowdown.

- Engage experts early:Consult professionals who know Texas code and can design permit-ready systems.

- Choose compliant, modular rack systems: Select racking that is pre-engineered for scalability and easily permits future expansion.

- Digitize your documentation: Keep current drawings, permit files, and inspection records organized for easy updates.

- Build in buffer time:Don’t wait until after installation to seek approvals. Loop compliance into your project timelines.

Want it all handled for you? Quantum Warehouse Solutions’ racking permit services provide end-to-end support, from layout to local approvals, so you can grow without the red tape.

Conclusion

Texas is growing, and so are your warehouse demands. Ensuring compliance with racking permits is a forward-thinking strategy that protects your people, your investment, and your ability to expand.

Whether you’re opening a new facility, upgrading automation, or just stacking higher, make compliance part of your plan, not an afterthought.

Let Quantum Warehouse Solutions help you scale the right way. Visit Quantum Warehouse Solutionsfor tailored guidance and permit-ready racking systems built to grow with you.