Table of Contents

ToggleSimplifying Warehouse Compliance: The Role of Annual Inspections and Audits

Master warehouse inspection requirements in Texas to ensure compliance and safety. Stay informed about auditsand enhance your warehouse operations effectively.

Effective warehouse compliance audits transform complex regulations into practical safety measures, significantly reducing fines, preventing accidents, and enhancing operational efficiency. With OSHA reporting over 95,000 warehousing injuries annually, proactive inspections and systematic audits are crucial for both risk mitigation and cost savings. In this guide, you’ll discover fundamental principles and key components of compliance audits, step-by-step safety audit procedures, hazard mitigation strategies, and continuous improvement strategies.

Table of Contents

- What Are Warehouse Compliance Audits and Why Are They Critical?

- How to Conduct Effective Warehouse Safety Audits: Step-by-Step Guidelines

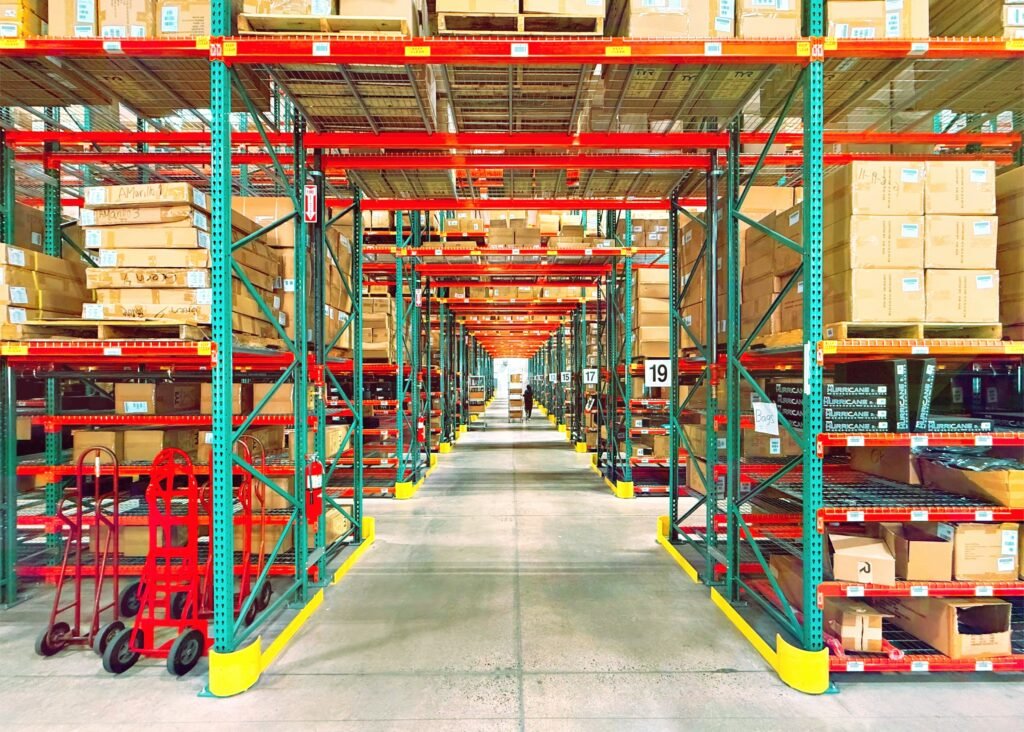

- What Are the Best Practices for Warehouse Racking System Inspections?

- How Can Continuous Improvement and Training Support Ongoing Warehouse Compliance?

- Conclusion

What Are Warehouse Compliance Audits and Why Are They Critical?

Warehouse compliance audits involve systematic reviews of facility operations, safety protocols, documentation, and physical infrastructure to ensure adherence to governmental standards. By pinpointing deficiencies in hazard communication, equipment upkeep, and emergency readiness, these audits foster a safer work environment and shield businesses from costly enforcement actions. Such audits evaluate processes against OSHA, FDA, and local codes, while simultaneously driving ongoing enhancements in risk management and productivity.

What Are the Key Elements of a Warehouse Safety Audit?

The essential components of a warehouse safety audit include:

- Personal Protective Equipment (PPE) Review – Verify the availability, proper training, and condition of helmets, gloves, and high-visibility apparel.

- Fire Safety Systems Inspection – Confirm the operational status of alarms, extinguishers, sprinklers, and ensure clear egress routes.

- Material Handling Assessment – Evaluate forklift operating procedures, load-capacity signage, and aisle clearances.

- Structural Integrity Check – Inspect pallet racking, shelving, and anchoring systems for any signs of damage or misalignment.

- Emergency Preparedness Drill Analysis – Review evacuation plans, the contents of first-aid kits, and staff training records.

A comprehensive audit identifies hidden risks, enforces accountability, and prepares the organization for reliable daily operations while ensuring readiness for external inspections.

How Often Should Warehouse Audits Be Conducted?

An annual warehouse safety audit serves as the foundation for compliance, supplemented by quarterly spot checks and monthly walk-throughs. Areas with high traffic and critical equipment zones should undergo weekly visual inspections.

A tiered schedule ensures that minor issues are addressed promptly, while in-depth assessments verify sustained compliance. This balanced frequency helps prevent audit fatigue and fosters an ongoing safety culture.

What Are the Benefits of Regular Compliance Audits?

Regular compliance audits provide:

- Risk mitigation by identifying hazards before accidents occur.

- Cost savings through the avoidance of fines, increased insurance premiums, and operational downtime.

- Operational efficiency by streamlining workflows and clarifying safety protocols.

- Reputational advantage by demonstrating a proactive commitment to workplace safety.

Consistent audit cycles reinforce a culture of continuous improvement and position warehouses for excellence in both productivity and regulatory standing.

How to Conduct Effective Warehouse Safety Audits: Step-by-Step Guidelines

A structured audit process transforms abstract regulations into measurable actions. Before diving into detailed inspections, gather pertinent safety manuals, previous audit reports, and training records. Then, proceed with these steps:

- Scope Definition – Clearly outline the areas, processes, and equipment to be assessed, ensuring alignment with regulatory requirements.

- Hazard Identification – Conduct a thorough walk-through of the facility to identify material handling risks, structural concerns, and gaps in PPE usage.

- Risk Evaluation – Assess the severity and likelihood of identified hazards, prioritizing corrective actions accordingly.

- Control Implementation – Assign specific responsibilities for necessary repairs, training updates, and procedural adjustments.

- Follow-Up Monitoring – Schedule re-inspections to confirm that remediation efforts have been successful and to document ongoing compliance.

This sequence promotes clarity, accountability, and a continuous feedback loop. Effective audits hinge on a well-defined scope, focused hazard analysis, and steadfast verification of improvements.

How to Develop a Comprehensive Warehouse Safety Program?

A robust safety program integrates policies, training, and ongoing monitoring:

- Develop clear standard operating procedures (SOPs) for equipment operation, emergency response protocols, and general housekeeping.

- Conduct regular employee training sessions covering hazard recognition, proper PPE usage, and incident reporting procedures.

- Implement digital tracking systems for audit findings and corrective actions, utilizing EHS or WMS platforms.

Embedding these elements into daily routines ensures that safety audits serve as a proactive tool rather than a reactive obligation, paving the way for a sustained culture of compliance and operational excellence.

What Are Common Warehouse Hazards and How Can They Be Mitigated?

Warehouse hazards range from equipment malfunctions to environmental exposures. Common risks and their corresponding solutions include:

- Forklift Collisions – Enforce strict speed limits, establish designated travel paths, and ensure operator certification.

- Slips and Trips – Maintain dry floor surfaces, keep aisles clear, and use visible signage.

- Racking Collapses – Conduct routine pallet rack inspections and promptly repair any damaged components.

- Chemical Spills – Store hazardous materials in approved containers, provide readily accessible spill kits, and train staff on containment procedures.

Addressing each hazard with targeted controls effectively reduces injury rates and supports a safer work environment, underscoring the critical value of detailed audit protocols.

Which Tools and Technologies Support Warehouse Safety Audits?

Modern audits benefit from software and hardware solutions that automate data collection and analysis. Key technologies include:

| Solution Category | Core Function | Operational Impact |

|---|---|---|

| Warehouse Management Systems (WMS) | Real-time inventory tracking and location management | Enhances visibility into storage conditions and material flow |

| EHS Compliance Platforms | Streamlined audit workflows and automated reporting | Simplifies tracking of findings and corrective actions |

| Mobile Inspection Apps | Digital checklists, photo documentation, and offline capabilities | Accelerates on-site assessments and data capture |

| IoT Sensors | Continuous environmental and equipment monitoring | Provides real-time alerts for temperature, humidity, or gas leaks |

Integrating these tools improves audit accuracy, expedites reporting processes, and elevates overall compliance performance, setting the stage for comprehensive facility-wide inspection management.

What Are the Best Practices for Warehouse Racking System Inspections?

- Train personnel to identify signs of damage such as bends, rust, or missing components during routine tasks.

- Maintain detailed inspection logs that include photographic evidence and timestamped notes.

- Engage certified professionals for annual structural assessments and load capacity validations.

- Immediately remove from service or clearly tag any damaged sections until repairs are completed.

Integrating these practices into daily operations ensures that minor damage does not escalate into catastrophic failures, directly supporting equipment inspection and maintenance strategies.

How Should Equipment Inspection and Maintenance Be Managed in Warehouses?

A centralized maintenance program is essential for scheduling preventive inspections for forklifts, conveyors, safety barriers, and fire suppression systems. Key steps include:

- Cataloging all equipment with serial numbers, recommended service intervals, and maintenance history logs.

- Automating work order generation within a computerized maintenance management system (CMMS).

- Conducting functional tests and meticulously documenting any deviations from expected performance.

- Escalating unresolved issues to supervisors for immediate attention and resolution.

This systematic approach to inspection management underpins both safety audits and compliance inspections warehouse, highlighting the interconnected nature of audit and inspection protocols.

How Do Compliance Inspections Differ From Audits?

While audits primarily focus on reviewing processes and documentation, compliance inspections emphasize the physical conditions and performance of equipment. Key distinctions include:

- Audits assess adherence to procedures, review training records, and evaluate hazard assessments.

- Inspections verify that structures, devices, and materials meet established safety standards on the warehouse floor.

Understanding this difference is crucial for effective scheduling, resource allocation, and reporting formats, bridging the gap between managerial oversight and on-site verification.

How to Manage Hazardous Material Storage Compliance in Warehouses?

- Ensure proper classification and labeling of chemicals using Safety Data Sheet (SDS) formats.

- Implement secondary containment systems and develop robust spill response plans.

- Conduct regular inspections to verify container integrity and assess ventilation adequacy.

By integrating these protocols into standard audit workflows, warehouses can maintain compliance across diverse material categories without resorting to siloed processes.

Why Are Racking Permit Services Important for Warehouse Compliance?

Engaging specialized permit services accelerates project approvals by ensuring:

- Engineering documentation is fully aligned with state and local building codes.

- Permit applications include comprehensive load-rating data and detailed design drawings.

- Effective coordination with inspectors to address potential questions prior to on-site reviews.

Quantum Warehouse Solutions’ racking permit services effectively bridge regulatory complexity and construction timelines, facilitating faster installations and guaranteed code compliance.

How to Implement Internal Warehouse Audit Procedures and Best Practices?

- Appoint a dedicated compliance coordinator to oversee audit schedules and reporting processes.

- Develop standardized audit templates that accurately reflect all relevant regulatory requirements.

- Train internal teams on audit procedures, proper data recording techniques, and corrective action workflows.

- Review audit outcomes regularly in leadership meetings and integrate key findings into ongoing safety programs.

Formalizing these steps fosters a sense of ownership, increases accountability, and transforms audits into proactive performance reviews.

How Can Continuous Improvement and Training Support Ongoing Warehouse Compliance?

Ongoing training programs reinforce correct procedures for equipment operation, hazard recognition, emergency response protocols, and documentation practices. Regular refresher courses ensure staff competency, mitigate risks associated with turnover, and align daily behaviors with audit findings. Continuous education directly contributes to improved compliance scores and enhanced workplace morale.

Frequent audits identify performance gaps early, while structured inspections validate equipment safety and procedural adherence. Combined analysis of audit reports and inspection records reveals trends that inform policy updates, technology investments, and targeted training initiatives. These feedback loops foster an environment where improvements are data-driven and sustainable.

How to Monitor Regulatory Changes and Update Compliance Programs?

Designate a specific compliance liaison to track updates from OSHA, FDA, IBC, and relevant state agencies. Subscribe to official regulatory bulletins, actively participate in industry forums, and review model code revisions annually. Integrate reviews of the audit program into standard operating calendars to adjust SOPs and training materials in response to new mandates, ensuring perpetual alignment with evolving standards.

Conclusion

Mastering warehouse compliance is an ongoing journey, not a destination. By integrating systematic audits, diligent inspections, and a proactive safety culture, you not only meet regulatory demands but also cultivate a more efficient, secure, and productive operational environment. Quantum Warehouse Solutions offers the expertise and tools to navigate this complex landscape, ensuring your facility operates at the highest standards of safety and compliance.

Don’t let compliance complexities hinder your operations. Contact us for personalized consultation and discover how our expert services can safeguard your facility, optimize your processes, and ensure lasting regulatory success.