Table of Contents

ToggleStep-by-Step: Avoiding Permit Mistakes on Your Warehouse Application

Avoid costly errors in your Texas warehouse permit application! Learn key tips to navigate the complex warehouse permit processand ensure compliance with all local and state regulationseffortlessly. This comprehensive guide will help you secure essential warehouse permitsand prevent common permit mistakes.

Securing the right warehouse permits is a crucial and often intricate step for any new construction, facility expansion, or significant operational change within your industrial space. This detailed guide provides practical insights and a clear, actionable path to enhance accuracy, simplify your submissions, and effectively steer clear of common permit mistakes during the entire warehouse application process. Understanding the nuances of Texas warehouse permit requirements is paramount for successful project completion and avoiding costly delays.

Table of Contents

- What Types of Warehouse Permits Are Typically Needed?

- How Do Building Codes and Fire Safety Regulations Influence Warehouse Permits?

- What Is the Step-by-Step Process for Applying for a Warehouse Permit?

- What Are the Most Common Warehouse Permit Application Mistakes to Avoid?

- How Does Not Seeking Expert Assistance Increase Permit Mistakes?

- What Are the Consequences of Warehouse Permit Mistakes and Non-Compliance?

- How Can Quantum Warehouse Solutions Help You Avoid Permit Mistakes and Save Time?

- What Are the State-Specific Warehouse Permit Requirements for Texas?

- Conclusion

What Types of Warehouse Permits Are Typically Needed?

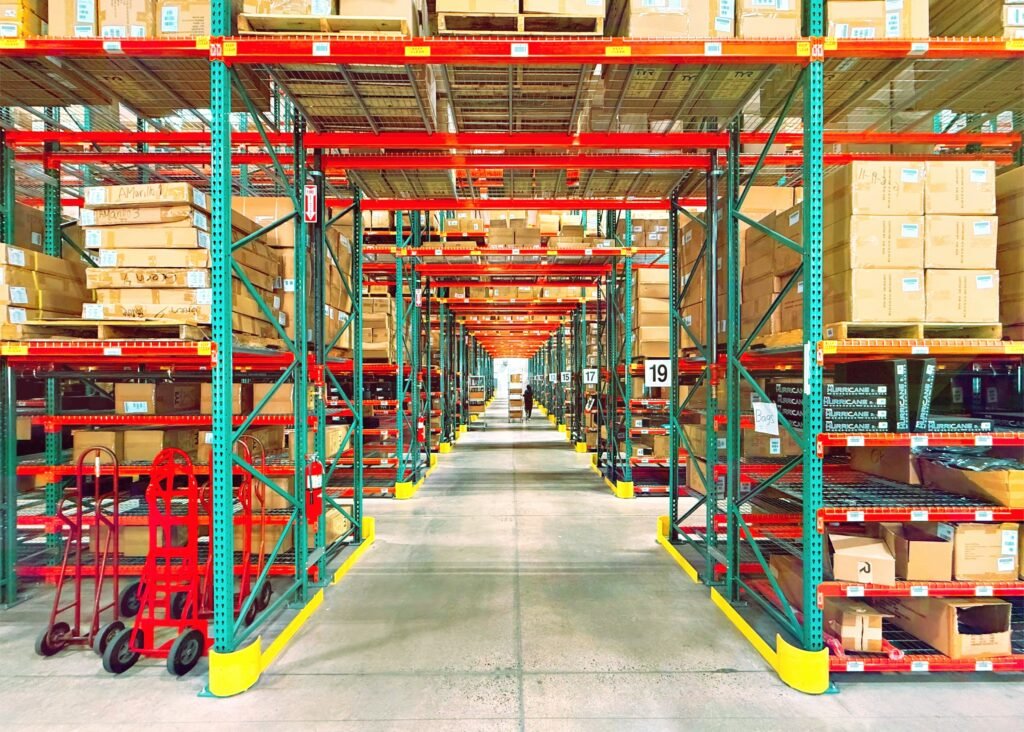

Warehouses, due to their diverse operational nature and structural complexities, often require a variety of specialized warehouse permits to guarantee structural soundness, operational safety, and environmental compliance. Key categories include essential building permits for any new construction, significant alterations, or structural modifications; fire safety permits for critical systems like sprinklers, alarms, and emergency exits; occupancy permits to confirm proper use classification and ensure the facility is safe for its intended purpose; racking permits for high-density storage systems; and hazardous materials permits if regulated substances are stored or processed on-site. Each specific warehouse permit is meticulously designed to safeguard a particular aspect of your operation or structure, significantly aiding in overall compliance and comprehensive risk management for your warehouse facility.

| Permit Category | Core Requirement | Issuing Authority |

|---|---|---|

| Building Permit | Approved construction plans, structural integrity, and code adherence | City or county building department |

| Fire Safety Permit | Sprinkler and alarm system design, fire suppression, and emergency egress plans | Fire marshal or local fire department |

| Occupancy Permit | Classification and use verification, ensuring safety for occupants | Local code enforcement office |

| Racking Permit | Structural calculations, layout, and installation compliance for storage systems | City or structural engineering office |

| Hazardous Materials Permit | Safety plans, containment measures, and environmental impact assessments | Environmental or fire agency |

Ensuring you accurately identify and secure all relevant permit types means every facet of your warehouse operations aligns with stringent safety and design regulations, setting a strong, compliant foundation for a successful warehouse permit application and long-term operational integrity. This proactive approach helps prevent costly warehouse permit mistakes.

How Do Building Codes and Fire Safety Regulations Influence Warehouse Permits?

Building codes establish the fundamental standards for construction, covering critical aspects like structural loads, safe egress pathways, seismic resistance, and material specifications. These codes are vital for ensuring the physical integrity and safety of your warehouse structure. Fire safety regulations, on the other hand, dictate specific requirements for automatic sprinkler coverage, fire-resistant materials, emergency access for first responders, and alarm systems. To achieve full compliance and secure your warehouse permits, you’ll need to submit detailed blueprints, comprehensive equipment specifications, and safety plans that demonstrate adherence to both sets of regulations. This meticulous documentation significantly increases your chances of prompt permit approval and drastically reduces the risk of costly on-site safety hazards or future permit mistakes.

What Is the Step-by-Step Process for Applying for a Warehouse Permit?

An organized and systematic warehouse permit application process involves a clear sequence of actions designed to maximize efficiency and minimize errors. This includes thorough research, meticulous documentation preparation, proactive pre-application discussions with authorities, accurate submission, and diligent follow-up inspections. Each stage is strategically designed to improve compliance, accelerate permit approvals, and ultimately benefit your project timelines and resource management, helping you avoid common warehouse permit mistakes.

- Conduct Comprehensive Research on Requirements: Begin by identifying all applicable state, county, and city building codes, fire safety regulations, and zoning ordinances. Verify the specific permit types needed for your project, including racking permits and fire suppression systems, and confirm the precise submission guidelines and fee structures for each agency involved in the warehouse permit application process.

- Prepare Thorough Documentation: Gather all necessary architectural plans, detailed structural calculations, comprehensive site layouts, and any required supporting studies, such as geotechnical or environmental reports. This thoroughness in your permit application documentation enhances clarity for reviewers and minimizes potential review comments or requests for additional information, preventing delays.

- Engage in Pre-Application Meetings: Schedule proactive meetings with local building officials, planning departments, and fire marshals. Use these invaluable sessions to clarify complex code interpretations, address specific site challenges, and gain early feedback on your proposed designs. This allows you to refine your design documents effectively before formal submission, significantly reducing the likelihood of permit mistakes.

- Submit Your Application and Fees: Deliver your complete warehouse permit application package, whether physical or digital, to the appropriate permitting office. Make sure to record your receipt numbers and submission timestamps, and confirm all required payments to ensure your review proceeds without unnecessary delay.

- Follow Up and Prepare for Inspections: Actively monitor your permit application’s progress through agency portals. Respond promptly and comprehensively to any plan review comments with revised documents and clarifications. Finally, prepare thoroughly for site inspections by code enforcement officers, ensuring all aspects of your warehouse construction or modification meet approved plans and regulations.

Adhering to this structured approach reduces uncertainty, mitigates risks, and builds a solid foundation for a compliant and successful warehouse permit application, ultimately saving time and resources.

What Are the Most Common Warehouse Permit Application Mistakes to Avoid?

Many warehouse projects encounter significant delays and increased costs due to frequent permit application errors. Recognizing and actively preventing these common pitfalls will dramatically improve the quality of your submissions and expedite permit approvals, thereby protecting both your project budget and your critical schedule. Avoiding these warehouse permit mistakes is absolutely crucial for project success.

- Incomplete or Inaccurate Documentation

Missing engineering drawings, incomplete site plans, or incorrect load calculations for racking systems often trigger immediate requests for corrections during the plan check phase of the permit application process. These corrections can extend review cycles by weeks or even months, leading to increased labor costs, material storage fees, and significant impacts on overall project timelines. This is a primary source of warehouse permit mistakes.

- Failure to Understand Local and State Regulations

Regulations differ significantly by jurisdiction, with each locality often having unique code amendments or specific submission requirements for warehouse permits. Failing to reference the correct edition of the building code or fire code, especially for Texas warehouse permit requirements, can result in non-compliant designs and outright application denials. This oversight is a common and avoidable permit mistake.

- Neglecting Pre-Application Engagement

Skipping early meetings with permitting authorities means missing valuable opportunities to clarify complex code interpretations and identify potential compliance challenges, such as easement restrictions, environmental impact considerations, or special inspection needs. These critical issues might otherwise surface much later in the application process, leading to costly project changes, redesigns, and significant delays. Proactive engagement helps prevent warehouse permit mistakes.

- Underestimating Timelines and Costs

Assuming a standard review period without factoring in potential agency backlogs, the complexity of your warehouse project, or the inevitable need for revisions can lead to severe budget overruns and construction delays. This can trigger contractual penalties, create resource conflicts, and negatively impact your business operations. Accurate planning for warehouse permit timelines is essential to avoid this critical permit mistake.

How Does Not Seeking Expert Assistance Increase Permit Mistakes?

Relying solely on in-house knowledge for complex warehouse permit applications might mean overlooking specialized permit types, missing recent code updates, or misinterpreting intricate regulations. Engaging expert consultants, particularly those familiar with Texas warehouse permit requirements, can significantly streamline the entire process by providing validated checklists, navigating bureaucratic hurdles, and accelerating approvals, thereby minimizing risk and preventing costly permit mistakes. This is especially important when dealing with complex Texas warehouse racking permits and other specialized warehouse permits. By proactively addressing these common errors with expert guidance, you can safeguard your project timeline and ensure your submissions consistently meet official expectations and regulatory standards.

What Are the Consequences of Warehouse Permit Mistakes and Non-Compliance?

Failing to secure or correctly process essential warehouse permits can trigger severe legal actions, substantial financial liabilities, and significant operational disruptions that far outweigh the initial permitting costs. These are significant warehouse permit mistakes with serious and far-reaching repercussions for your business and project.

| Penalty Type | Impact | Real-World Example |

|---|---|---|

| Fines and Penalties | Can increase project budgets by up to 20% or more, impacting profitability. | A local agency imposed daily fines for ongoing warehouse construction after a critical building permit had expired, leading to thousands in unexpected costs. |

| Stop-Work Orders | Immediate cessation of all construction activities, causing project delays and contractual breaches. | A warehouse expansion project was halted for 30 days pending the resubmission of corrected plans and a new fire safety permit. |

| Business Shutdowns | Temporary or even permanent suspension of warehouse operations, resulting in lost revenue and reputational damage. | Non-compliant fire safety installations led to a temporary closure ordered by the fire marshal, disrupting supply chains. |

| Legal Liabilities | Potential lawsuits from injured parties, property damage claims, or environmental violations. | A warehouse operating without proper hazardous materials permits faced a major lawsuit after a chemical spill. |

Understanding these potential consequences underscores the critical importance of meticulous compliance planning, accurate submissions, and proactive management of all warehouse permit requirements. Avoiding warehouse permit mistakes is not just about saving money; it’s about safeguarding your entire operation.

How Can Quantum Warehouse Solutions Help You Avoid Permit Mistakes and Save Time?

Quantum Warehouse Solutions utilizes its extensive industry expertise and deep understanding of Texas warehouse permit requirements to guide your entire warehouse permit process from initial research through final approval, ensuring maximum efficiency, regulatory certainty, and complete compliance. Our goal is to help you avoid common warehouse permit mistakes and streamline your project.

- Expert Guidance on Permit Requirements: Our seasoned specialists conduct a comprehensive assessment of all applicable building codes, fire safety regulations, and local ordinances. We meticulously identify every relevant permit type—from building permits to racking permits and hazardous materials permits—and clarify complex code interpretations to prevent any costly oversights or permit mistakes.

- Professional Assistance to Ensure Compliance: Our dedicated permit consultants meticulously review all project documentation for accuracy, completeness, and adherence to regulatory standards. We facilitate crucial pre-application meetings with permitting authorities and coordinate necessary revisions to expedite plan approvals, ensuring your warehouse permit application is flawless.

- End-to-End Application Support: Clients benefit from centralized project management, transparent status tracking through every stage of the application process, and comprehensive compliance assurance. This allows your internal teams to concentrate on core warehouse operations and project execution, knowing that your warehouse permits are being expertly managed.

Partnering with Quantum Warehouse Solutions significantly enhances the quality and accuracy of your submissions and dramatically reduces the time and resources spent navigating complex permitting landscapes, ultimately helping you avoid warehouse permit mistakes and achieve faster project completion.

What Are the State-Specific Warehouse Permit Requirements for Texas?

Warehouse permitting in Texas involves a unique blend of both statewide codes and locally adopted amendments that significantly affect structural, fire safety, and site development standards. Addressing these state-specific nuances is key to safeguarding your permit approval timelines and effectively integrating regional safety priorities into your warehouse permit application. Understanding Texas warehouse permit requirements is critical for any project in the state.

Texas has officially adopted the International Building Code (IBC) 2021 Edition, including appendices C, F, and K, which became effective on July 1, 2024. Additionally, the International Energy Conservation Code (IECC) 2015 Edition is currently in effect, dictating energy efficiency standards for warehouse construction. These codes establish the baseline for building permits and structural integrity across the state.

Fire safety regulations in Texas specifically mandate automatic sprinkler coverage for high-piled storage areas within warehouses and impose additional stringent requirements in hurricane-prone coastal areas. These measures are designed to enhance structural resilience, protect valuable inventory, and ensure occupant safety, making fire safety permits a critical component of any Texas warehouse permit application. Furthermore, specific racking permits are often required, with detailed engineering plans to ensure stability and safety for high-density storage systems.

Conclusion

Securing the right warehouse permits is not merely a bureaucratic step; it is absolutely essential for ensuring comprehensive compliance, operational efficiency, and the long-term success of your warehouse project. By thoroughly understanding the various permit types required, diligently following the step-by-step application process, and actively avoiding common warehouse permit mistakes, you can significantly streamline your project timelines, reduce unexpected costs, and mitigate potential legal liabilities. Engaging with experienced experts like Quantum Warehouse Solutions can provide invaluable support throughout the complex permitting process, helping you navigate the intricacies of the warehouse application process and effectively avoid costly warehouse permit mistakes, especially when dealing with specific Texas warehouse permit requirements.

Take the next crucial step towards a successful, compliant, and efficient warehouse project by exploring our specialized services today. Let us help you secure your warehouse permits with confidence.

Contact Quantum Warehouse Solutions for a hassle-free warehouse permit application process and to avoid warehouse permit mistakes.