Table of Contents

ToggleWhat Are Warehouse Racking Permits & Why Are They Required in Texas?

Maximize your storage efficiency with essential warehouse racking requirements in Texas. Learn about permits and regulations to optimize your workspace today!

Understanding warehouse racking permits Texas is crucial for any business operating within the state. Missing or incorrect permits can lead to costly fines, project delays, and increased liability, so understanding every requirement is vital. This guide defines the permits you need, explores safety and code obligations, and addresses common warehouse racking permit challenges with solutions.

Table of Contents

- What Are Warehouse Racking Permits in Texas?

- What Types of Warehouse Racking Permits Exist in Texas?

- How Do Permits Ensure Compliance with Building and Fire Codes?

- What Defines High-Piled Storage Under Texas Fire Codes?

- How Does the International Fire Code Chapter 32 Apply to High-Piled Storage?

- What Fire Suppression and Sprinkler System Requirements Must Be Met?

- How Do You Obtain a Warehouse Racking Permit in Texas?

- What Are the Ongoing Compliance and Maintenance Obligations After Permit Approval?

- What Are the Key Compliance Factors for Texas Warehouse Racking?

- How Does Fire Code Compliance Affect Warehouse Racking Design?

- What Are the Structural and Seismic Design Requirements for Racking Systems?

- How Do OSHA Regulations Impact Warehouse Racking Safety?

- Why Is Load Capacity Labeling Important for Warehouse Racking?

- What Are Common Challenges in Obtaining Warehouse Racking Permits in Texas and How Can They Be Overcome?

- Conclusion

What Are Warehouse Racking Permits in Texas?

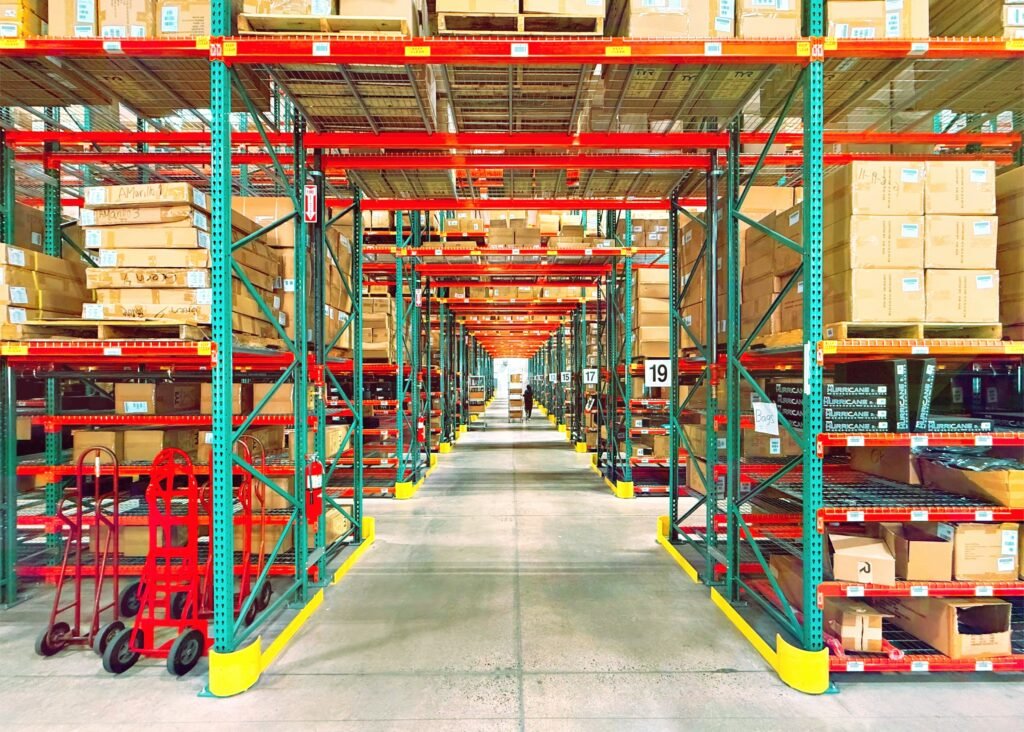

Warehouse racking permits in Texas are formal approvals issued by local authorities to verify that proposed racking designs meet structural, fire, and safety standards before installation. These permits ensure that racking systems are designed and installed in accordance with relevant safety guidelines, local building requirements, and zoning rules. Obtaining the correct storage racking permits Texas ensures compliance and safety.

What Types of Warehouse Racking Permits Exist in Texas?

Two primary permit categories address different storage scenarios and safety risks.

- General Racking Permits apply to fixed systems under high-piled storage thresholds.

- High-Piled Storage Permits cover combustible materials stored above defined heights and require enhanced fire suppression designs.

| Permit Type | Trigger | Key Requirement |

|---|---|---|

| General Racking Permit | Racks over 5 ft 9 in in height | Submit structural calculations |

| High-Piled Storage Permit | Storage exceeding 12 ft height | Design per IFC Chapter 32 + NFPA 13 |

These classifications guide whether a standard plan review suffices or if specialized fire marshal approval is mandatory.

How Do Permits Ensure Compliance with Building and Fire Codes?

Local building and fire authorities reference the International Building Code (IBC), International Fire Code (IFC Chapter 32), and NFPA 13 standards to validate plans.

International Building Code (IBC)

The International Building Code (IBC) is a model building code developed by the International Code Council (ICC) and has been adopted for use as a base code standard by most jurisdictions in the United States. The IBC addresses both health and safety concerns for buildings based upon prescriptive and performance-related requirements.

International Fire Code (IFC)

The International Fire Code (IFC) provides fire prevention and safety standards for existing buildings and is a model code that regulates minimum fire safety requirements for new and existing buildings, facilities, storage, and processes. The IFC is often referenced by local authorities when reviewing warehouse racking plans.

- Require hose and sprinkler coverage for flue spaces between racks.

- Mandate fire-resistant materials and egress routes as part of layout reviews.

- Enforce commodity classification rules that dictate storage height limits.

By integrating these codes early, permits prevent unanticipated retrofits and align your facility with state and national regulations.

What Defines High-Piled Storage Under Texas Fire Codes?

Under Texas fire codes, high-piled storage refers to the vertical arrangement of combustible commodities that exceeds:

- 12 ft for general goods in solid piles or racks.

- 6 ft for high-hazard materials like Class III and IV commodities.

- 500 ft² of floor area per pile segment.

Commodity classification further refines these limits, ensuring that fire risk drives the review scope and suppression design criteria.

How Does the International Fire Code Chapter 32 Apply to High-Piled Storage?

International Fire Code Chapter 32 prescribes permit triggers and plan reviews for high-piled combustible storage, specifying:

- Permit requirements for locations where rack top elevations exceed thresholds.

- Fire marshal authority to inspect and approve storage layouts.

- Mandatory documentation of commodity classification and pile configurations.

Fire marshals enforce these rules to mitigate rapid fire spread in dense storage environments, leading into suppression system design mandates.

What Fire Suppression and Sprinkler System Requirements Must Be Met?

High-piled storage areas must integrate sprinklers designed per NFPA 13 to control fire intensity and protect rack integrity. NFPA 13 provides standards for the design and installation of automatic fire sprinkler systems.

| Sprinkler Standard | Flow Rate | Minimum Clearance |

|---|---|---|

| NFPA 13 Light Hazard | 0.10 gpm/ft² | 18 in between sprinklers |

| NFPA 13 Ordinary Hazard I | 0.15 gpm/ft² | 24 in from rack top |

| NFPA 13 Ordinary Hazard II | 0.30 gpm/ft² | 36 in from sprinklers |

These specifications reduce fire spread through flue spaces and crown slopes, ensuring adequate water distribution for combustible loads.

How Do You Obtain a Warehouse Racking Permit in Texas?

Securing a warehouse racking permit in Texas involves understanding local variations, engaging licensed professionals, and following a clear application pathway from planning through inspections. Navigating warehouse racking permits Texas requires diligence. Permit fees, submittal procedures, and plan review timelines differ by city.

For example, Dallas requires two-part structural and fire plan reviews with county-specific fee schedules. Houston mandates online plan uploads and a separate fire district permit. Austin enforces additional site-specific erosion control documentation. Knowing these nuances early prevents resubmissions and accelerates approval.

What Are the Ongoing Compliance and Maintenance Obligations After Permit Approval?

Maintaining permit validity hinges on regular assessments and updates. Perform periodic structural inspections to detect rack damage or misalignment and schedule annual fire system tests and clearance verifications. Submit modifications or expansions for plan review before making changes. Also, you should keep engineering documents and permit copies accessible for audits.

Proactive maintenance preserves safety and avoids citation risks over a warehouse’s lifecycle.

What Are the Key Compliance Factors for Texas Warehouse Racking?

Effective rack design marries fire protection, structural integrity, load management, and operational safety to fulfill local and federal regulations. Meeting all warehouse racking requirements is essential.

How Does Fire Code Compliance Affect Warehouse Racking Design?

Rack layouts must integrate flue spaces and sprinkler heads to prevent fire bridging between aisles.

When designing storage rack layouts in warehouses or distribution centers, one critical aspect to consider is the integration of flue spaces and sprinkler heads. Flue spaces refer to the gaps left between the storage racks and products to ensure proper airflow and prevent the risk of fire spreading.

Adequate flue spaces allow sprinklers to operate effectively by ensuring that water can reach all areas of the rack. If the racks are too tightly packed without sufficient space, it may lead to fire bridging, where flames can easily jump from one aisle to another, posing a significant safety risk. Therefore, maintaining these spaces is not just a recommendation, but a requirement to comply with fire safety regulations.

In addition to flue spaces, proper placement of sprinkler heads is essential in mitigating fire hazards. Sprinklers must be strategically positioned to cover all reachable areas while accounting for the height and density of stored goods. This ensures effective fire suppression without creating any blind spots that could allow a fire to grow unchecked. By carefully planning rack layouts that integrate both flue spaces and sprinkler systems, businesses can significantly enhance fire safety measures.

This proactive approach not only protects valuable inventory but also safeguards the well-being of employees and minimizes potential damage to the facility. Therefore, always prioritizing fire safety during the rack design phase is a foundational step in ensuring a safe and efficient storage environment.

What Are the Structural and Seismic Design Requirements for Racking Systems?

Even in low-seismic areas, the International Building Code mandates anchoring and bracing to resist lateral forces. That’s why it is important to anchor rack uprights with threaded rod or epoxy anchorage rated for uplift, include cross-beam bracing at defined intervals for horizontal stability, and verify beam-to-column connections with manufacturer-approved fasteners. These measures ensure racks remain vertical under operational and environmental loads.

How Do OSHA Regulations Impact Warehouse Racking Safety?

OSHA mandates that all warehouse racking must be capable of supporting the maximum intended load and must be labeled with the maximum load capacity. OSHA also requires that workers who operate material handling equipment around racking be properly trained on safe operating procedures. Compliance fosters safe material handling and minimizes accident potential.

Why Is Load Capacity Labeling Important for Warehouse Racking?

Clearly displayed load plaques inform operators of maximum allowable weights per level to prevent overloading. This is a critical part of warehouse racking requirements. Place metal capacity labels on each upright at eye level. Detail uniform and concentrated load limits in pounds or kilograms and update labels promptly when structural modifications occur. Accurate labeling guards against structural collapse and safeguards workers below.

What Are Common Challenges in Obtaining Warehouse Racking Permits in Texas and How Can They Be Overcome?

Permit applicants often encounter incomplete documentation, jurisdictional confusion, and unexpected review comments that stall project timelines. Addressing these hurdles early accelerates approval. Understanding warehouse permit laws Texas can help mitigate these challenges. Double-check that all drawings bear a current engineer’s seal. Include fire protection hydraulic calculations per NFPA 13 and label aisles, exits, and storage commodities clearly on plans. Addressing these points prevents rejection cycles and shortens review durations.

Working with permit consultants and structural engineers ensures that all code references and documentation standards are met. Consultants will audit your application for completeness against local checklists, liaise directly with plan reviewers to clarify technical questions, and expedite resubmittals by providing revision guidance and updated drawings. Their experience cuts administrative overhead and moves installations forward efficiently.

Conclusion

Understanding and obtaining warehouse racking permits in Texas is crucial for ensuring safety, compliance, and operational efficiency. By adhering to these regulations, businesses can avoid costly fines and enhance their reputation while protecting their employees and assets. Engaging with licensed professionals simplifies the process and fosters a culture of safety and accountability. Take the next step to secure your warehouse’s future by consulting with experts.

Quantum Warehouse Solutions offers racking permit consultation services to ensure your warehouse racking is compliant, safe, and efficient. From initial design to final inspection, we’re your trusted partner in Texas. Contact Quantum Warehouse Solutions today!